Embarkation Ladder Regulations

Embarkation ladders form part of a vessels safety equipment. Details of the required number of ladders a vessel requires can be found on the safety equipment certificate.

Embarkation ladders fall under Life Saving Apparatus and are therefore regulated under SOLAS Chapter III. SOLAS offers the following definition

Embarkation ladder is the ladder provided at survival craft embarkation stations to permit safe access to survival craft after launching.

SOLAS goes on to add the following requirements

An embarkation ladder complying with the requirements of paragraph 6.1.6 of the Code extending, in a single length, from the deck to the waterline in the lightest seagoing condition under all conditions of trim of up to 10° and a list of up to 20° either way shall be provided at each embarkation station or at every two adjacent embarkation stations for survival craft launched down the side of the ship. However, the Administration may permit such ladders to be replaced by approved devices to afford access to the survival craft when waterborne, provided that there shall be at least one embarkation ladder on each side of the ship. Other means of embarkation enabling descent to the water in a controlled manner may be permitted for the liferafts required by regulation 31.1.4.

So we now know the length of ladder required needs to reach from the deck to the waterline when the vessel has a trim of 10° and an adverse list of 20°. The vessels shipyard drawings should have schematics indicating the length of embarkation ladder needed to comply with this condition.

The ladders should be inspected each month as part of the normal LSA inspection schedule.

The detailed construction standards of the embarkation ladder can be found in ISO 5489 (2008). Their construction is very similar to that of a pilot ladder but greater flexibility is allowed in terms of construction methods and materials.

Materials Used In Embarkation Ladders

The general construction materials are

Any wooden parts are hardwood (e.g. ash, oak, elm, beech, teak or apitong) free from knots.

Each side rope shall be mildew-resistant manila rope or a spun thermoset polyester rope with a polypropylene core of a colour that contrasts with the spun polyester. Each side rope shall have a breaking strength of at least 24 kN, and a nominal diameter of 18 mm

Alternative side ropes of thermosetting polymer may be used if they meet the breaking strain requirement, offer similar resistance to stretching, offer a similar gripability as manilla or spun polyester, are resistant to deterioration from sunlight, provide a visual indication of excessive wear as spun polyester does.

Metal components need to be corrosion resistant and plastic components must be resistant to outdoor weathering.

Any seizing need to be two or three ply marline or other similar material.

Embarkation Ladder Construction

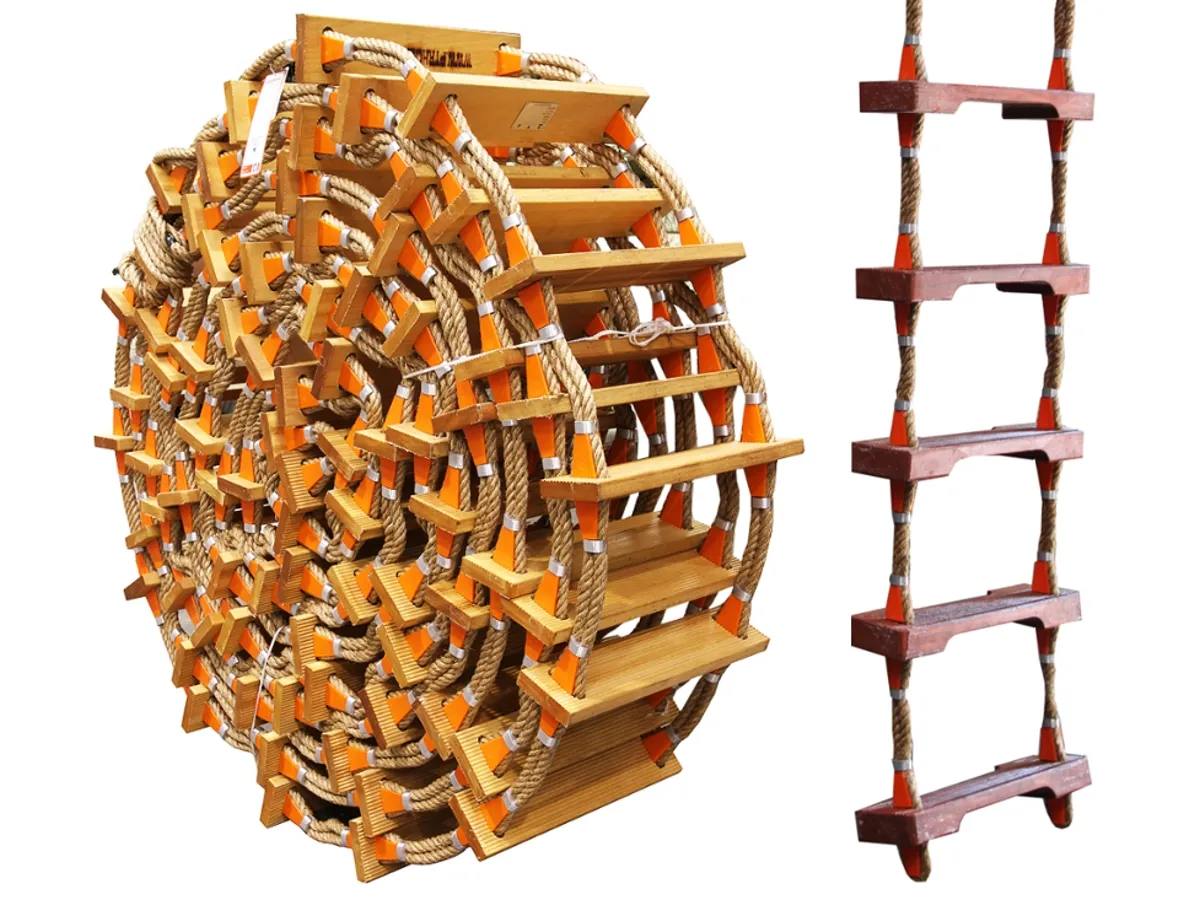

As with a pilot ladder the embarkation ladder can consists of 2 uncovered side ropes on each side however unlike pilot ladders it is also possible to be of three string construction with a third set of ropes in the middle of the ladder. As with a pilot ladder the side ropes must be continuous from top to bottom.

The tops of the embarkation ladder are generally finished with thimbles and terminated at the bottom with either a splice or alternative fixing method but the ends of the rope need to be whipped to prevent fraying.

The fitting of steps and step fixtures in an embarkation ladder generally mimics the design of a pilot ladder being but can be wider than 400mm although the distance between steps is identical (330mm +/- 20mm). The steps are a minimum of 25mm thick and can be wood, plastic or rubber with a non-slip surface. As with a pilot ladder 2 steps can be replaced providing it does not require the ladder to be unstrung and restrung.

The ladder must be able to be rolled up and unrolled freely and hanging vertically.

Embarkation Ladder Marking & Identification

The bottom of at least 2 steps need to be marked with the manufacturers name and address, the model designation, ISO 5489 and SOLAS, the year of assembly and the name of the approving maritime safety administration.

Replacement steps need identifying as such on their underside along with the manufacturers details, year of manufacture, SOLAS and ISO 5489 and approval administration details.

Embarkation Ladder Retesting

As with an ISO 799 pilot ladder an ISO 5489 embarkation ladder requires a 30 month retest. Once the retest has been carried out the ladder needs marking to indicate who carried out the test and when it was undertaken.

Ladders that fail the test need to be replaced or rebuilt.

Major construction differences between an ISO embarkation ladder and a pilot ladder

As can be seen there are many similarities with a pilot ladder however there are also many differences. The main difference is the lack of spreaders on an embarkation ladder. Spreaders would make storage of embarkation ladders on the boat deck quite difficult so are not a requirement of their construction.

Next the width of a pilot ladder is fixed due to the stipulation of a 400mm step width whereas steps only need to be a minimum of 400mm on an embarkation ladder.

The steps can be wood, plastic or rubber and there is no requirement for the bottom 4 steps to be rubber as these ladders don’t have to deal with the same amount of punishment caused by pilot boats landing heavily on them.

Finally embarkation ladders can have a three string construction, although we have never encountered one yet!

Management of Embarkation Ladders

Managing embarkation ladders can be a real headache. Thankfully as well as managing your pilot ladder arrangements Fathom Safety can also manage your embarkation ladders as well. Our end to end management service can cover all of your fleets embarkation ladders and we will ensure they are inspected, maintained and replaced or retested at the correct interval whilst ensuring vessel managers and superintendents maintain complete visibility of their vessels ladders with our bespoke vessel ladder management interface.