Pilot Ladder Winch Damage

Having a pilot ladder on a winch is a convenient way to deploy and more importantly recover your pilot ladder easily especially on vessels with a large freeboard. The alternative of a manually deployed pilot ladder is an arduous and potentially dangerous task for the crew.

However winch deployed pilot ladders come with their own issues that have potential to damage the ladder both on the winch and when recovering the ladder. Here we will look at the different causes of pilot ladder winch damage.

Difference Between a Manually Deployed Pilot Ladder And Winch Deployed Pilot Ladder

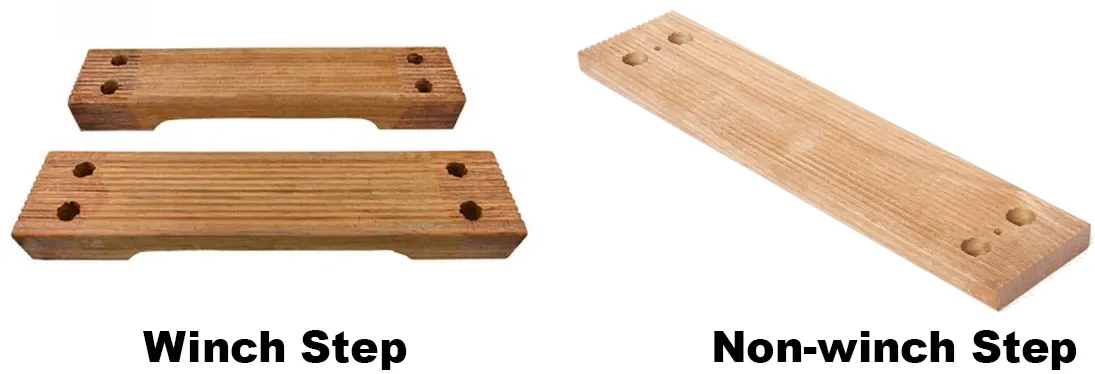

The design of winch ladder and non-winch ladders is verry different. A winch ladder will have much thicker ends where the wedges are positioned. This makes the ladder much more robust and capable of withstanding any damage if the crew do not take care in recovering the pilot ladder. Non-winch pilot ladders have steps that are a consistent depth across their whole length, this make the ladder lighter and therefore much easier for the crew to recover.

Winch Damage To The Pilot Ladder

Winches present 3 dangers to the pilot ladder that are frequent causes of damage. Being aware of these causes will help vessel managers buy the correct ladder and a vessels crew prevent against them occurring.

Pilot Ladder Winch Drum Securing Points

Some badly designed winches can have large protruding pad eyes on the spindle for the connecting of the ladder or tails to the winch. The larger these pad eyes are the greater they protrude from the spindle the greater the risk that when the pilot ladder is recovered these pad eyes will press up against the ladder and potentially damage the wedges, steps or securings.

Pilot Ladder Winch Spindle Diameter Issues

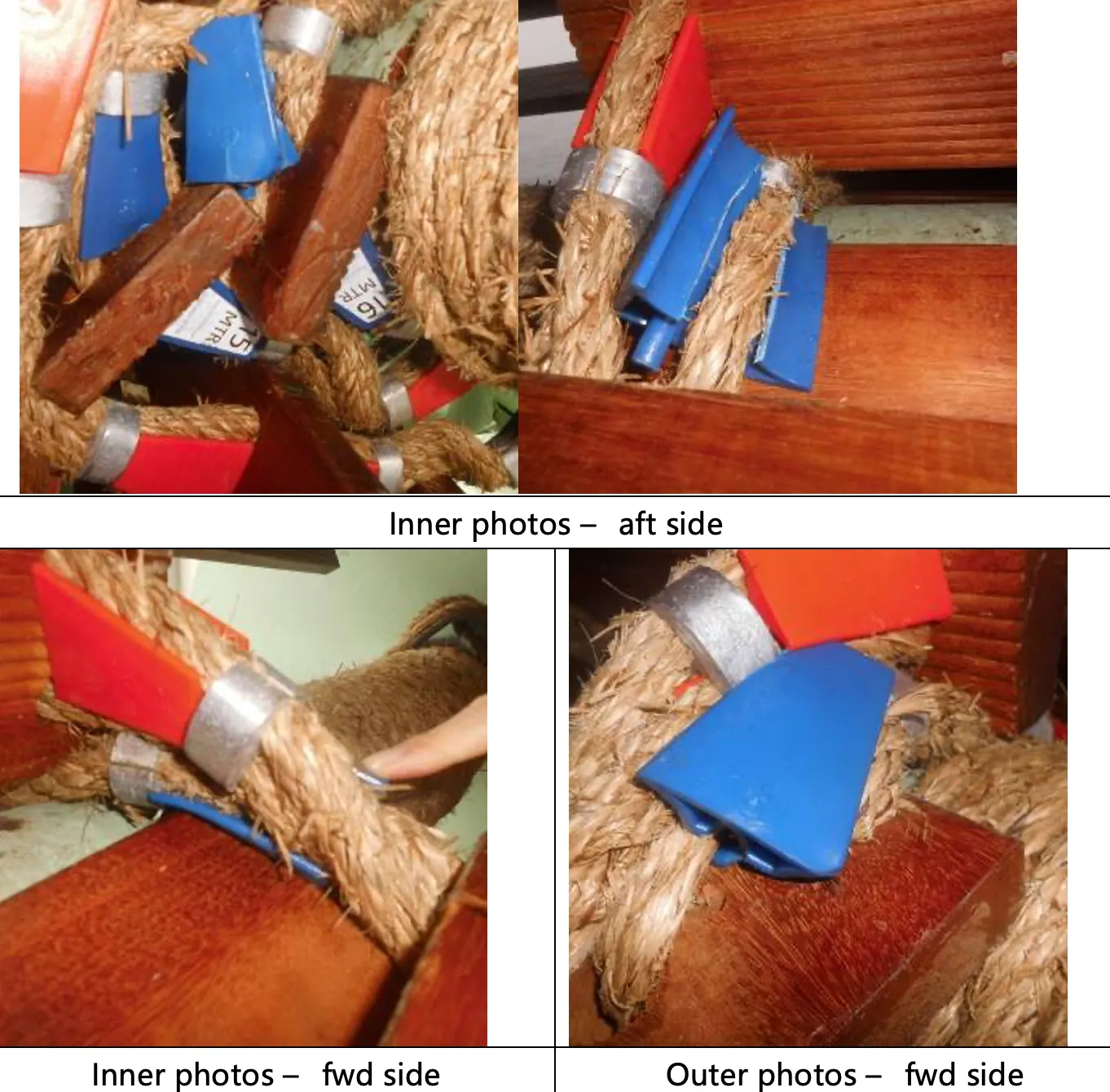

Many pilot ladder winches have very narrow diameter spindles which can cause serious issues to a pilot ladder. The small diameter of the spindle combined with the power of the winch can cause the ladder to be drawn tightly onto the spindle and due to the circumference of the spindle being small than the distance between the steps can cause serious damage.

In these photos the damage caused to the wedges is quite clear. These plastic components are designed purely to keep the step level and are very easily crushed.

One method Fathom Safety employs to prevent this from happening on vessels in our pilot ladder management service is to order ladders that have 5 rubber steps AT THE TOP of the ladder. These rubber steps effectively increase the diameter of the spindle prior to the ladder components are wound on. This has been a very effective method of preventing pilot ladder winch damage, but it is essential the vessels officers are aware of the purpose of these steps and that they understand the steps do not form part of the functioning ladder in case a maritime pilot or class surveyor should query the design. The ladder does remain fully compliant with SOLAS V/23 and ISO 799 with this adaptation.

Careless Recovery Of A Pilot Ladder

The hydraulic or air driven motors on many pilot winches are quite powerful and there is always a danger that should a pilot ladder become snagged on the deck edge, deck furniture or similar that the winch will force the ladder against the obstruction and potentially damage the ladder.

It is important that when recovering the ladder there are 2 AB’s and a responsible office. The responsible officer is required to conduct a post use inspection whilst the pilot ladder is recovered and this leaves one AB to operate the controls whilst the other supervises the pilot ladder’s recovery preventing it from becoming snagged and able to signal to his colleague to stop hauling if it should.

A Better Design Of Pilot Ladder Winch

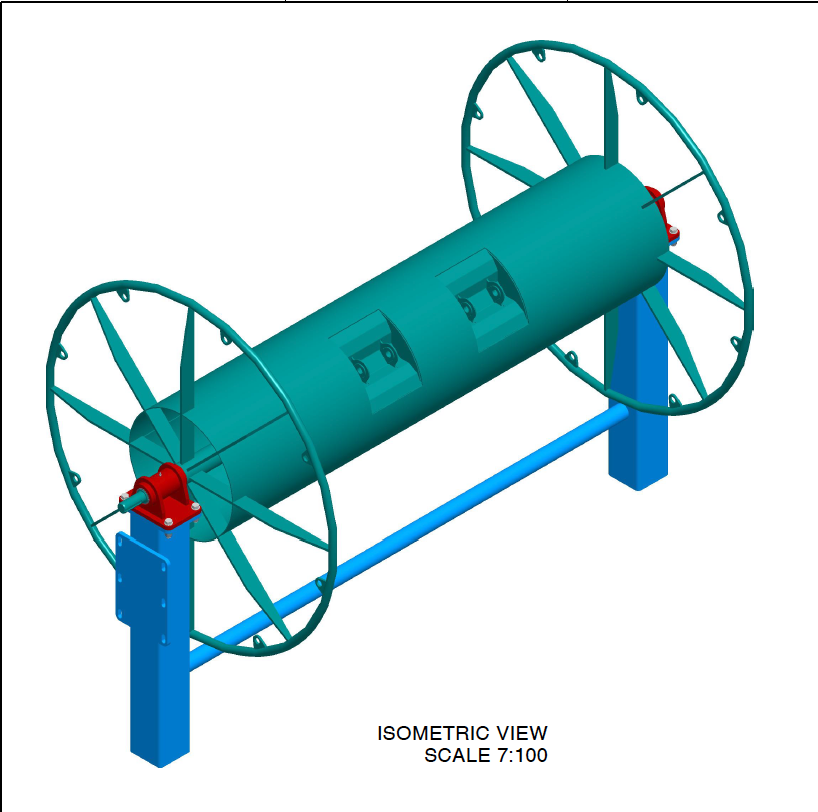

Our partners at PTR Holland have produced a design of pilot ladder winch that corrects some of the issues that lead to damage of winch deployed pilot ladders.

Their new winch design has a much wider diameter spindle and is fitted with recessed fixing points that don’t interfere with or damage the ladder. These two adaptations prevent the vast majority of the damage we see on pilot ladders. It simply needs proper supervision to eliminate the other causes.